Engineering Portfolio

Biomimetic Finger

In order to understand how to control prosthetic limbs through electromyography, I built the simplest complete actuator I could imagine. I used the Sparkfun Myoware 2.0 EMG sensor attached to my forearm to control a biomimetic index finger. This task required coding a microcontroller to take a running average of the muscle tones to find the range of muscle tones it will receive, create ranges for each type of movement, and then update 50 times per second to follow the user's movement. I 3D modeled the finger after my own using Fusion 360 and used fishing wire to simulate the tendons in the finger. The documentation for the project is available here.

Custom Fidgets

Fidgets offer tactile stimulus to occupy restless energy that can disrupt concentration. Frustrated by noisy, distracting mainstream options, I design quiet, tactilely satisfying fidgets to subtly enhance focus.

I originally designed "the perfect fidget" for myself, but when my peers asked to buy it from me, I knew I had to make something for them. Inspired by their feedback, I use CAD tools and 3D printing to refine my tactile and mechanical actions to create a compelling user experience.

In fact, when placed in public settings, my creations rarely sit idle for long; people instinctively reach for them, effortlessly channeling distraction into calm productivity.

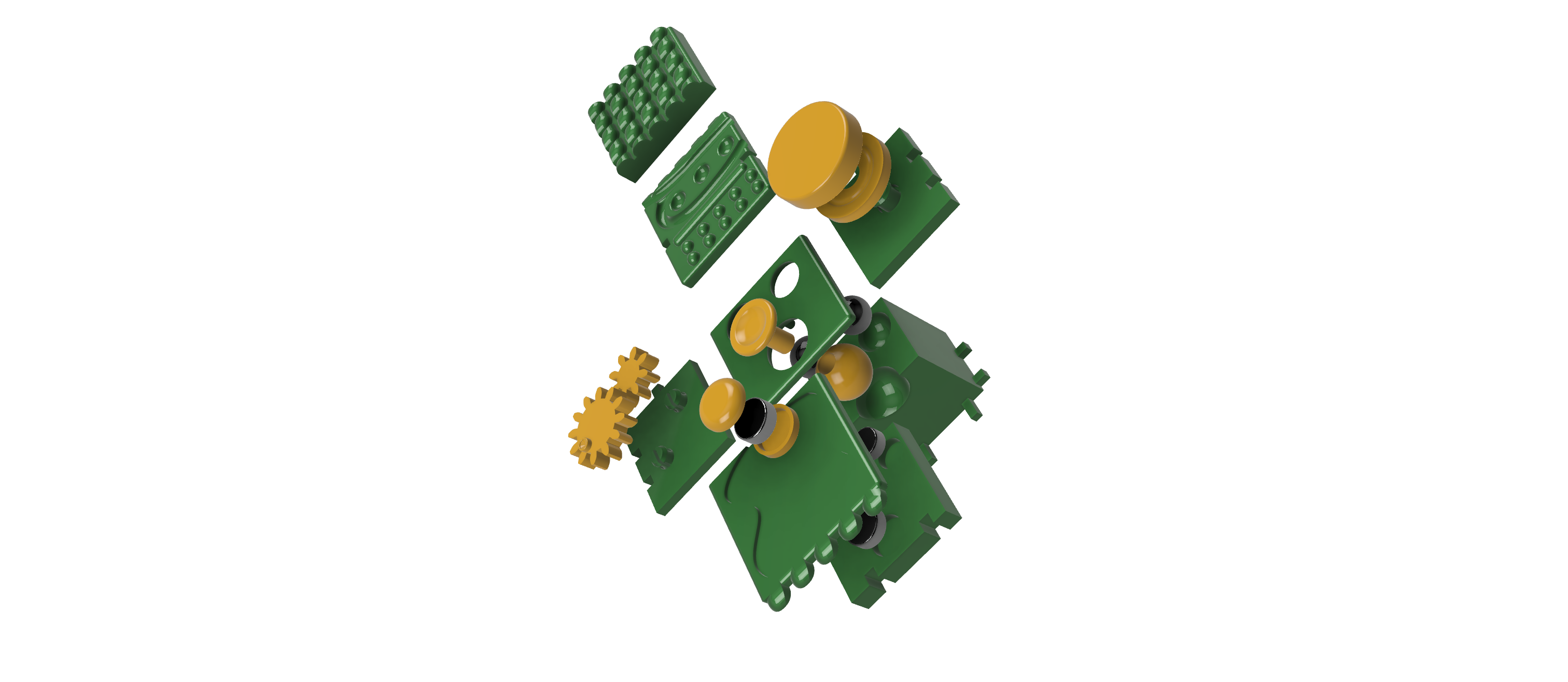

Fidget Cube

- Six different combinations of textures and dynamic tactile experiences.

- Magnetic slider, embedded ball bearings, gears, wheel, and joystick.

- All in a 1¼ inch cube.

Diamond Spinner

2 identical magnetic sides that rotate about a pin. Satisfying in its simplicity. Comes in variety of colors.

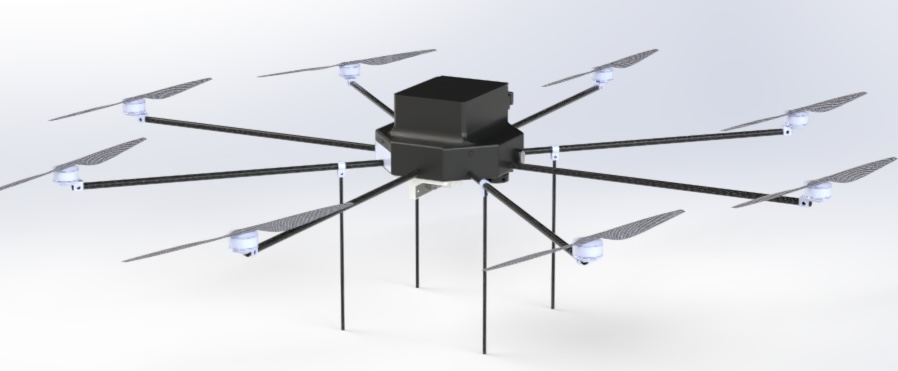

Package Delivery Drone

I designed a drone with 7 of my peers to deliver packages up to 16"x16"x12" and 4lbs within a 1.5 mile radius of the take off zone. I researched, documented, and ensured compliance with all FAA guidelines regarding our drone delivery system. Specifically designed the package dropping and loading mechanism with minimal points of failure and minimal cost. Our team presented progress updates throughout the design process.

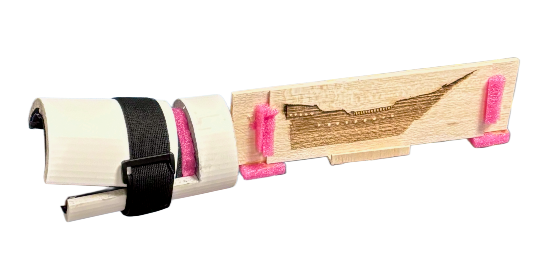

Prosthetic Card-holding Hand

As a class project, I prototyped a card-holding prosthetic for a below-elbow amputee. Features include:

- Sweat wicking adjustable attachment points

- Scrabble-like holder with a capacity of 25 playing cards (6 if sides do not overlap)

- Customizable front design

- The card-holding portion can be detached easily to stand on a flat surface

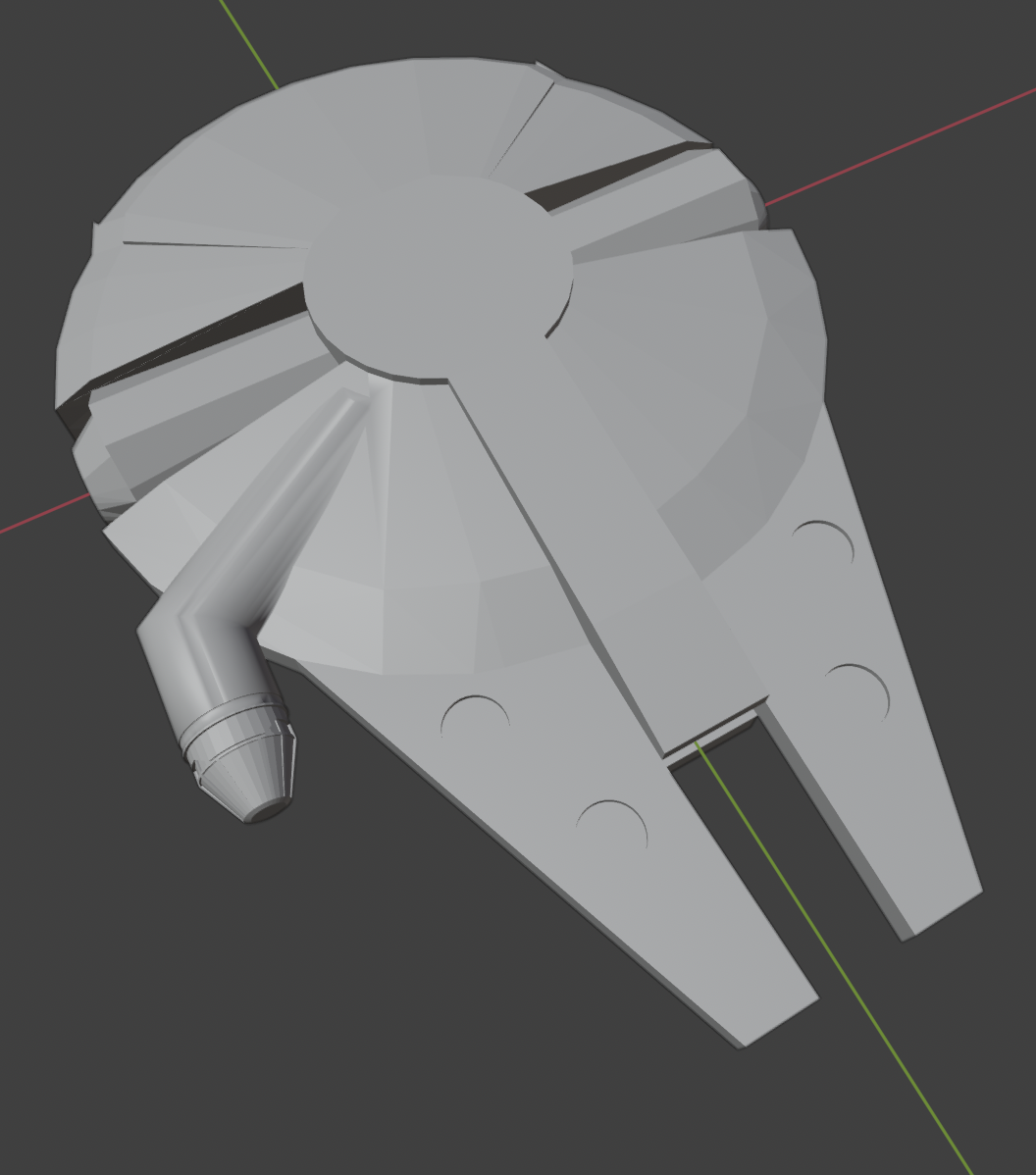

Millennium Falcon

I taught myself how to use Blender and Fusion 360 by modeling the Millennium Falcon from Star Wars from reference photos. Using my university's 3D printer to print the ship inspired me to get my own printer.

I am currently modeling the ship in Solidworks.

0.005" Tolerance Hammer

During a manufacturing class at Case Western, I learned the fundamentals of metal machining enabling me to make a hammer with 0.005" tolerances.

The tools I used to make this steel hammer include:

- Bandsaw

- Lathe

- Mill

- Reamer

- Drill press

- Counterbore

- Countersink

- Benchtop Grinder and Polishing Wheel

- Threaded Tap Wrench

- CNC mill

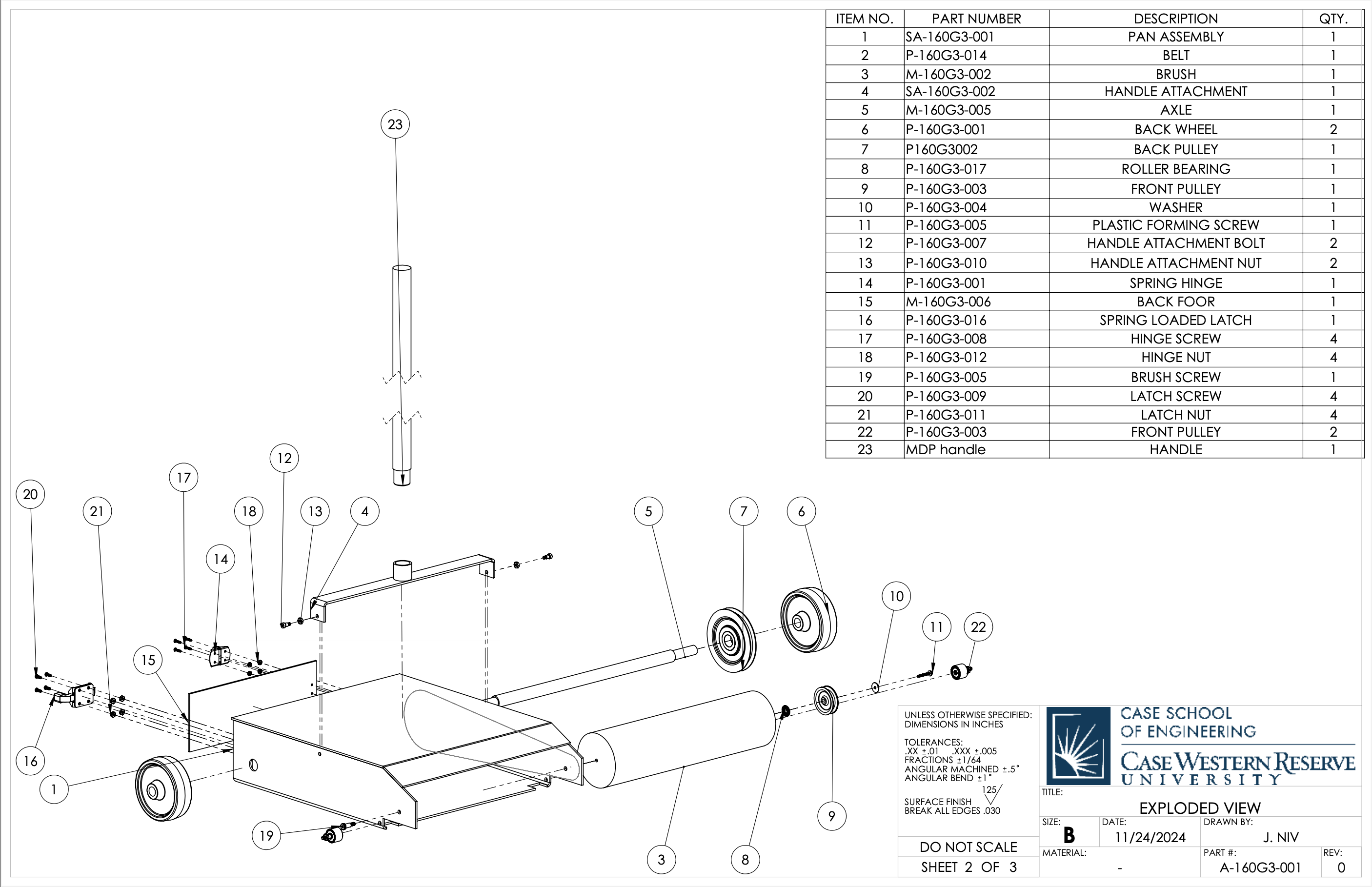

Carpet Sweeper

As part of a group project, I designed a broom with a belt-driven brush, to work as an unpowered vacuum cleaner. The design complied with Case's engineering documentation standards. It was manufacturable with the tools available in a standard machine shop, and had a cost of materials in line with the purpose it served.